Contact US

- [email protected]

- +86 15095059907

- Times Headquarter, No. 15 Lianxiang Str, Jinan, Shandong

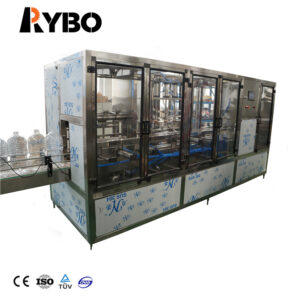

- Capacity: 8000~10000 Bottle Per Hour

- Bottle Sizes: 250ml ~2000ml

- Function: Bottled Water Washing Filling Capping

Share to:

We can supple turnkey production line for pure water, mineral water, drinking water, soda water, flavored water, natural water, spring water, potable water, flavoured water with different bottle packages.

What does Turnkey/complete water production line includes :

1. Bottle Blowing System make PET plastic bottles ( Semi automatic / Fully automatic )

2. Water Treatment System purify water (Sand filter, Carbon filter, RO/UF, Ozone sterilizer, UV sterilizer and etc.)

3. Air conveyor for empty bottle loading

4. Rinser-filler-capper 3 in 1 monoblock

5. Cap loader load caps

6. Code printer (Ink-jet printer/ laser-jet printer)

7. Labeling Machine (PVC sleelve labeling machine/OPP Hot Melt Glue Labeling Machine / Self-adheisive labeling machine)

8. End packaging ( PE Shrink Wrapping Machine / Carton packing machine )

Flow chart: (Pure water filling machine):

A) Bottle production line PET Resin –Injection moulding machine -Botlte blowing machine –PET bottle

B) Water treatment system Raw water–Pump–Silica sand filter–Carbon filter–Water softner–Reverse Osmosis -UV sterilizer-Ozone generator–Finished water tank

C) Filling&Packing part Bottle unscrambler–Air conveyor–Washing,filling,capping 3in1 machine–Light checker–Blow dryer–Dater printer–Lableing machine –Packing machine -Stock

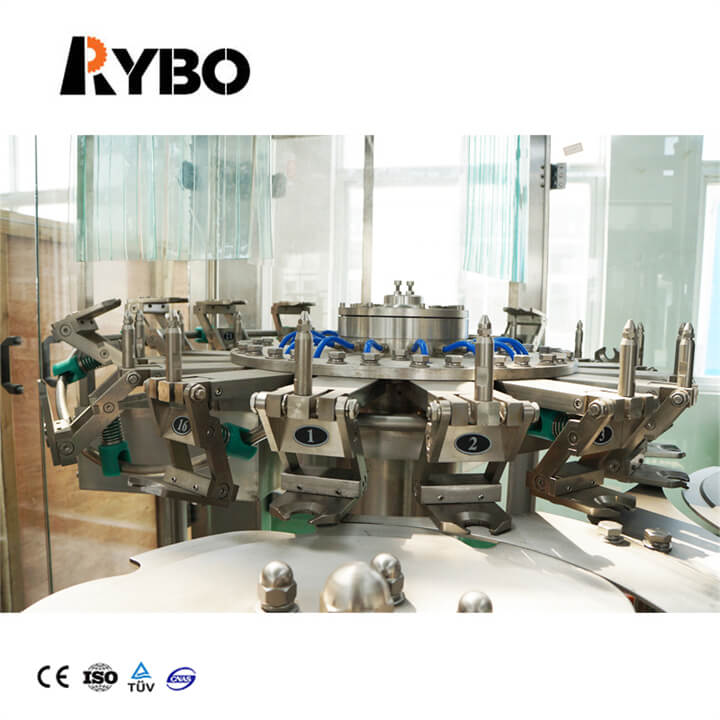

Main Description:

This Machine mainly used in the water filling operations, the three function of bottle washing, filling and capping are composed in one body of the machine, the whole process is automatic, it is conveniently turnked to adjust the machine to fill various types of bottles, the filling operation is faster and more stable due to the advanced filling valve technology, The famous brand programeed controller (PLC) is adopted to control the machine runs automatically. it is a ideal perferred equipment for beverage makers .

Technical Parameters:

| Function :Washing / Filling / Capping System | |||

| Suitable for: PET bottles with screw cap | Bottle sizes : 250ml ~ 2L | ||

| Filling system: Gravity filling | Capacity: 8000 ~10000BPH | ||

| Application: still water, pure water, RO water, mineral water, sparkling water, etc. | |||

Equipment structure:

1. Rinsing system: Combined with rotary tray with clamp, water distributing tray, water tank and rinsing pump.

2. Filling system: Combined with hydraulic, filling valve, controlling ring, and elevator-cylinder.

3. Capping system: Combined with capper, cap sorter and cap falling track.

4. Driving system: Combined with main motor and gears.

5. Bottle transmitting system: Combined with air conveyor, steel starwheels and neck supporting carrier plates.

6. Electrical controlling system: this part is frequency inverted, PLC controlled and touch screen operated.

How to Maintain one automatic water filling machine:

Every shift of production shall carry out an overall clean of machine and the inspection of the fixing parts to ensure no looseness either at beginning or at the end.

If the meshing of gears is not satisfactory the remedy work shall be carried out and lubricate the gears with grease at last.

When the seasonal production is finished or any temporal stop of production happens in a year, an overhaul shall be carried out and the wearing-and-tearing parts should be replaced ensuring the satisfactory production of next term.

Notes:

1) When cleaning, forbid any water spray over rotating or electrical parts;

2) Bottles and caps shall accord with technical requirement and any discord ones shall be forbidden to be applied lest causing mechanical failure;

3) Each interconnecting of drive-and-driven pairs shall be precisely adjusted lest any bottle-blocking will occur;

4) Regular inspection of lubrication spots and ensuring satisfactory lubrication.