Contact US

- [email protected]

- +86 15095059907

- Times Headquarter, No. 15 Lianxiang Str, Jinan, Shandong

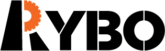

- Capacity: 300~2000 Bottle Per Hour

- Bottle Sizes: 2000ml ~5000ml

- Function: Bottled Water Washing Filling Capping

Share to:

Products Introduction

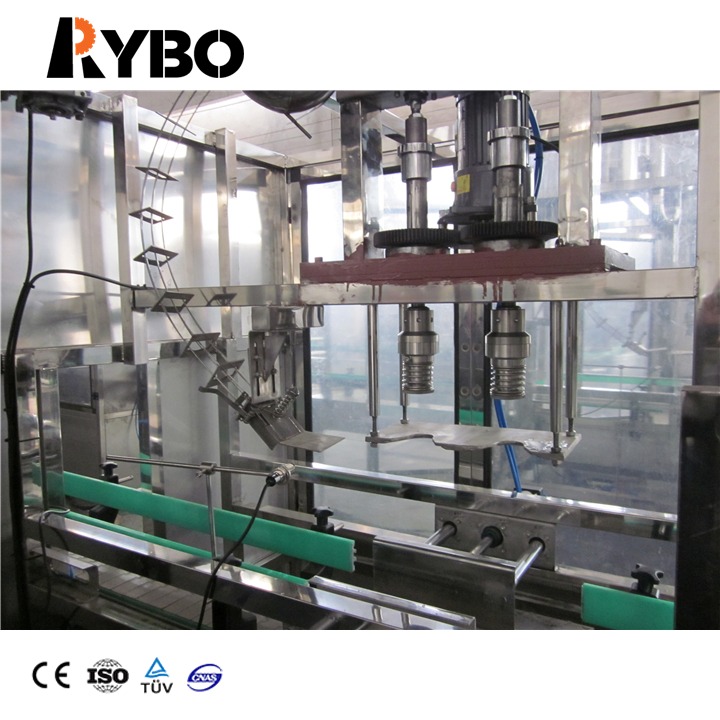

This 5L and 10 Liter machine combines disinfection washing, filling and capping three functions into one assembly line. Mainly used for liquid filling, it is moderate, simple structure, easy maintenance.

Works procedure

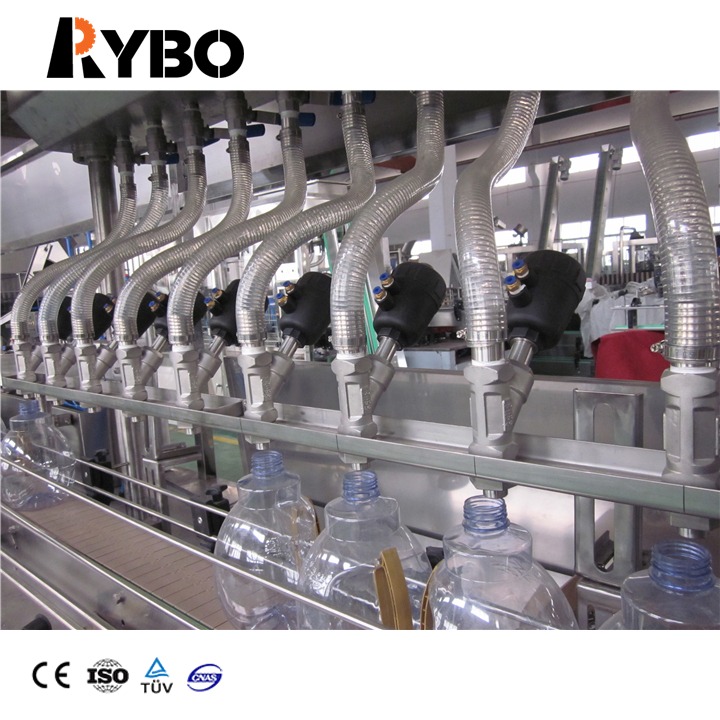

1. When the bottles straight from the chain of humanitarian sent to the first machine rinser; the machine in motion, in the Under the action of cam, so that folder open bottle clip and contraction of the bottle rotated 180 degrees for washing and disinfection.

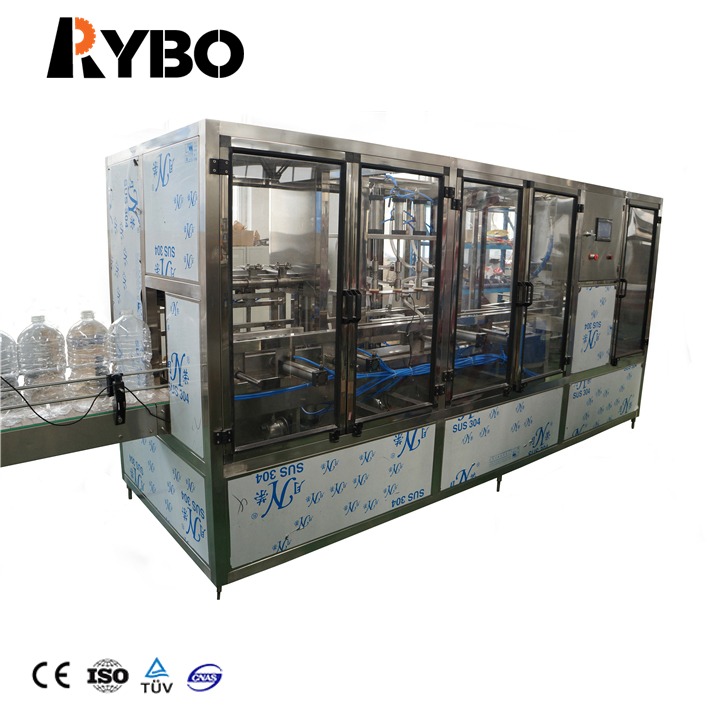

2. Continue to operate, the bottle returned to the original point of view. And the open clip, under the influence of the bottle in the Jog Dial to enter delivery systems. Then transported to the filling machine parts, filling machine parts has a photoelectric detection, when the bottle is only through the Ba, the optical data into information to the PLC, PLC had instructed the cylinder block to block bottles .

3. Bottle filling machine rear cylinder block has also played, keep an empty bottle into the capping machine. Under the action of the program, filling the cylinder downward movement, so that within the filling valve into the bottle filling, until a certain time to stop filling, the cylinder block bottles back. Filled bottle into the capping machine, capping machine from the rack, the justifications for cover device, and even the composition of gland. Gland it is connected to the horizontal section of the dump under a certain angle, the constant movement when the bottle, put on caps. Then the bottles with catchy article closely aligns with the gland, gland play a role.

Main Characteristics

Washing Heads: 3-18

Filling Heads: 3-18

Capping Heads: 1-6

Suitable Bottle Size: 2-10L PET Bottle

Capacity: 300-2000B/h

Power Supply: 380V 50HZ

Atmospheric pressure: 0.5 ~ 0.7mpa